STANDARDS: EN 12390–2, ASTM C31, C192, C511

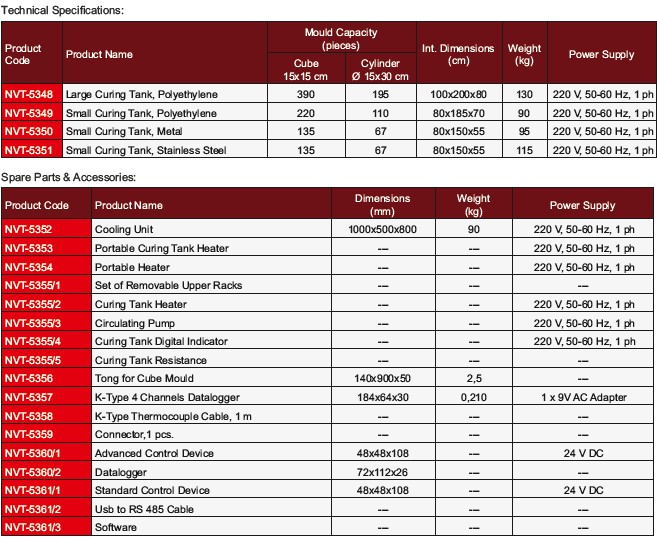

Curing Tanks are designed for curing concrete cubes and cylinders.

The temperature can be adjusted and can be kept constant by an electric resistance incorporating a digital thermo regulator which maintains the set temperature between ambient to 40 ºC with ± 2 ºC accuracy.

Supplied complete with Thermostat Controlled Heater, Base Metal Rack and Submersible Circulator Pump.

Cooling Unit is available as optional. Cooling Unit (should be factory installed) should be ordered separately.

Tong for Cube Mould should be ordered separately.

K-Type 4 Channels Datalogger is available as optional. RS 232 Interface and 16000 memory capacity. Resolution is 0,1°C in -200,0°C...+200°C.

K-Type Thermocouple Cable and Connector should be ordered separately.

Standard Control Device is available as optional. Standard Control Device has 2 pieces 4 Digit Display, Auto-Tuning (automatic setting of PID parameters), Sensor Fault Detection. Usb to RS 485 Cable is needed an should be ordered seperately.

Advanced Control Device with Datalogger is available as optional. Advanced Control Device has 2 pieces 4 Digit Display, PID Heating/Cooling, Auto-Tuning (automatic setting of PID parameters), Automatic/Manual Operating Modes, Sensor Fault Detection. Datalogger for Advanced Control Device has 5 pieces Isolated Analog Input Channel, USB 1.1 and 2.0 Compatible PC Connection, Unlimited Recording Capacity, Excel, Access, Text, HTML and PDF reporting format.