STANDARDS: EN 12390-3, 12390-4; BS 1881, ASTM C39

Automatic range of 600 kN, 1500 kN, 2000 kN and 3000 kN Capacity Compression Testing Machines have been designed for reliable and consistent testing of a wide range of specimens. Machines confirm all EN, ASTM and BS standards written above. These also meet the requirements of CE norms for the safety and health of the operator.

Testing machines are supplied with EN compression platens as standard. Machines also comply with the ASTM C39 standard when used together with suitable platens.

Tests can be performed by either Digital Readout Unit or on a computer with using free Software.

The Automatic Compression Testing Machines allow inexperienced operators to perform the tests. Once the machine has been switched on and the specimen is positioned and centered by the help of centering apparatus. The only required operations are;

• Setting test parameters, including pace rate (only required when the specimen type is changed).

• Pressing the START button on the control unit.

• The machine automatically starts the rapid approach, when the specimen touches the upper platen the rapid approach is ended and starts loading at the pace rate that selected by user and stops once the specimen fails.

The Automatic Concrete Compression Testing Machines consist of;

• Load Frame,

• Automatic Hydraulic Power Pack,

• Digital data acquisition & control system,

• Distance Pieces, 30 mm, 50 mm and 80 mm,

• Upper Platen (with ball seating assembly),

• Lower Platen,

• Loading Cylinder Assembly & Limit Switch for safety,

• Front and Rear Protective Doors for safety.

Concrete Compression Load Frame

Capacities of 600 kN, 1500 kN, 2000 kN and 3000 kN Load Frames are most popular and available models for welded type frames.

The load frame provides the stability needed for accurate and repeatable test results over the years of operation.

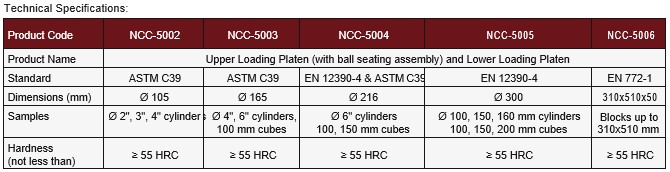

Upper Platens / Lower Platens

The platens enable the testing of a wide variety of cylinder, cube blocks or similar samples.

• Manufactured from high quality steel, which is then hardened, smoothed and finished.

• The roughness value for the surface texture of the auxiliary platens is ≤ 3.2 µm.

• Ø 165 mm, Ø 216 mm and Ø 300 mm Upper Platen (with ball seating assembly) and Lower Platen have centering rings on the lower platens for proper centering of 100 mm and 150 mm cube, 100 mm and 150 mm cylinder samples.

• Ø 300 mm Upper Platen (with ball seating assembly) and Lower Platen has an specimen centering apparatus on lower platen as standard 150 mm cube and Ø 150 mm cylinder.

Block Platens with Sliding Rail Assembly

STANDARDS: EN 772-1, 12390-4

Product Code: NCC-5001

Block Platens with Sliding Rail Assembly are installed on the compression testing machines for testing concrete blocks and other structural materials. The Sliding Rail Assembly allows the platens to be easily installed without removing the existing Ø 300 mm compression platens. This assembly should be factory installed.

It should be noted that after installing, the vertical clearance between the platens decreases by 50 mm.

Block Platens Lifting Assembly is used for easy removal of the lower platen of Block Platens and easy replacement of the distance pieces between the piston and the lower platen.

Distance Pieces

Distance pieces are used to reduce the amount of vertical clearance between the upper platen and the lower platen.

.jpeg)

The maximum ram stroke is 50 mm, a limit switch is fitted to prevent over travel of the regard to the capacity.

All frames have a single acting up stroking ram. The diameter of piston changes with ram which cuts the power to the pump for safety.

At the end of the test process to start a new test the piston returns to default position. The pressure transducer is used for load measurements.

There is a low friction coaxial PTFE seal between the cylinder and the piston fitted to the cylinder.