Description

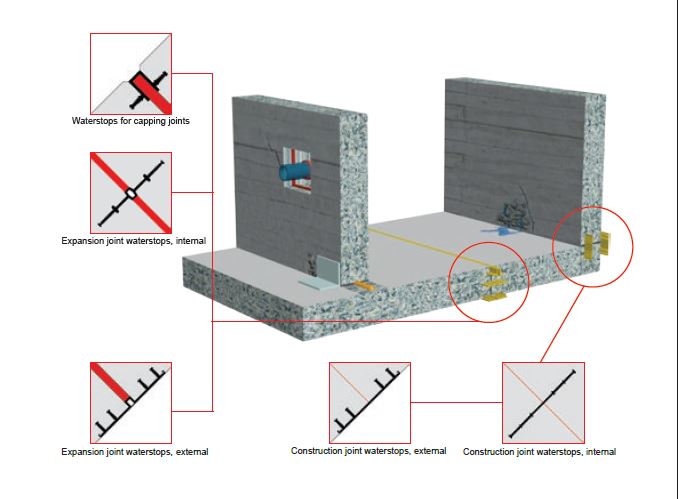

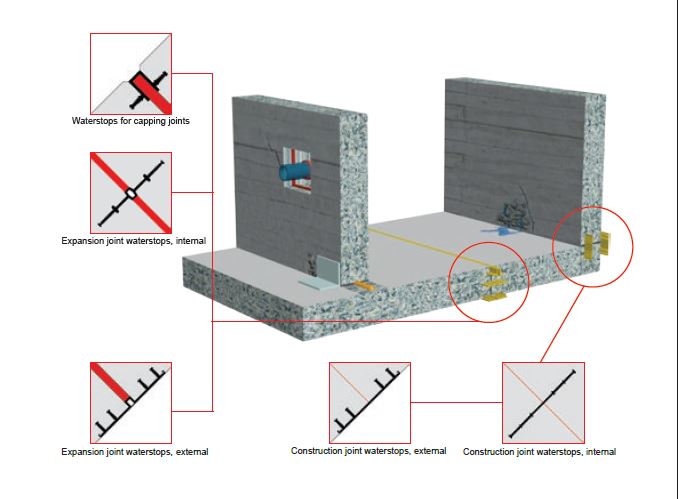

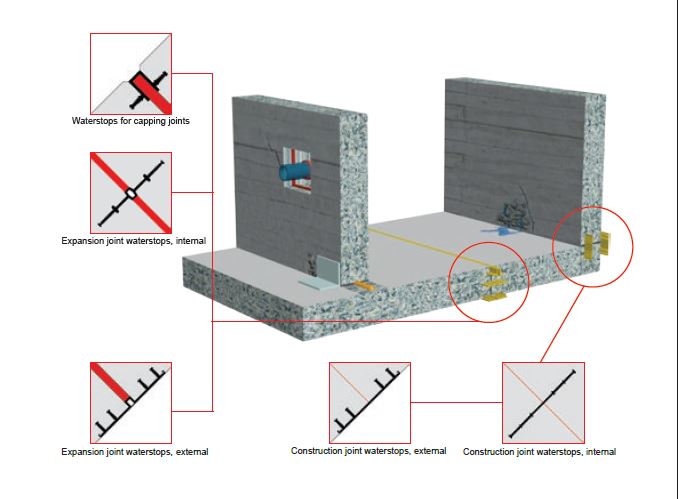

The wide range of P.V.C waterstops are designed to provide an integral sealing system for movement and construction joints in concrete cast in-situ. These joints typically occur in the following types of structure.

Typical Applications

For Construction and Expansion Joints, all Types of Joints in Transitions, Connections and Special Applications.

Waterstop Specification

Design:

- Closed Waterproofing System Waterstops must create a closed waterproofing system within the reinforced concrete structure. Joint intersections with each other and with penetrations and edges of the structure should be made as square as possible. The clearance from the edges of the structure should generally be 0.5 m minimum. The overall waterstop section system specification and method statement for a project are divided into logical sections. These are linked to the drawings of the system and its components, their factory prefabrication or assembly and for their installation on site. This also provides part of the project documentation and confirmation of the specific waterstop qualities required. The waterstops should conform with the local regulations and specifications.

- Protected Storage

When delivered to site, the waterstop products must be unloaded carefully and inspected immediately for completeness and integrity, including form and dimensions. Before installation the waterstops must be kept in a sheltered place on boards or some other firm base (e.g. pallets, concrete surfaces) and protected from contamination or damage

- Storage in Summer

Waterstops must be protected from direct sunlight, specially in summer, e.g. by covering. In high outside temperatures waterstops must be taken to the point of installation and laid out under no tension.

- Storage in Winter

Waterstops should be kept in covered storage if possible and then be put in heated rooms for at least one full day prior to their installation, to make their handling and installation easier and less prone to damage (thermoplastic material).